Despite President Trump’s denial, climate change is real and we need to act. Decarbonizing our productive model (i.e., minimizing our greenhouse gases emissions or even suppressing them) has become one of the biggest challenges that scientists, technologists and policy makers are facing. Lately, low carbon technologies for power generation (mainly solar and wind) are starting to win the fight against fossil fuels and the contribution of renewables is increasing rapidly all around the world. Despite this increasing role, these low carbon technologies are still unable to fulfil our needs. As a consequence, we are still struggling to reduce greenhouse gases emissions in areas such as heating buildings, transportation fuels and production of chemicals, which account for a really big chunk of the greenhouse gases.

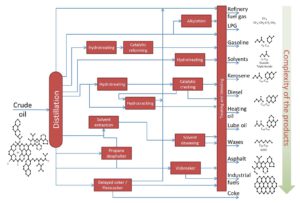

Fuels and the majority of the chemical products that we use today are produced in refineries and have a common origin: oil. In the refinery, oil undergoes a lot of transformations through different processes with fancy names (fractioning, fluid catalytic cracking, visbreaking…). The objective of this series of processes is to transform a complex and useless feedstock into other products that can be sold for different applications (see Figure 1). However, from the chemical point of view, this is just a transformation of a messy mixture of carbon, hydrogen and oxygen atoms (along with other minor components like metals, sulphur or nitrogen) into simpler molecules.

Figure 1. Simplified scheme of the processes involved in a refinery and the products obtained of oil.

Now, let´s take a look at the organic matter with a biological origin: plants, our organic residues at home, residues for the agriculture and cattle…this is called biomass. Biomass (get ready to hear something familiar), from the chemical point of view, it is basically a complex mixture of carbon, hydrogen and oxygen atoms (along with other minor components like metals, sulphur or nitrogen)…rings a bell, right? Yes, it is much the same thing as oil! Well, not in all aspects, as there are some differences in the contents and the organization of the single components. For example, oil is much richer in carbon while biomass has higher contents of oxygen. Then, if biomass is so similar to oil… why not switching the feedstock and start producing chemicals and fuels in a more sustainable way? That is the idea behind the development of biorefineries.

Then, a question arises: why is it so difficult to substitute oil for biomass (if they are so similar) and we still produce most of our fuels and chemicals from oil? You may have heard a lot of times about the power and influence of oil industry. I recognize this as a reality and a potential burden for the future deployment of biorefineries. But right now, the burdens are mainly technical. We cannot apply exactly the same technologies that we use for processing oil in the processing of biomass. Here is where those differences mentioned play a key role. The different contents and organization of the basic components of oil and biomass (mainly carbon, oxygen and hydrogen) strongly affect the way in which they react and the products formed when they are processed. For example, just heating up oil, several different fractions can be produced. These fractions, after some further processing, can be converted into gasoline, kerosene, waxes, lubricants or combustible gases. On the other hand, if we heat up biomass, we obtain only three fractions (solid, liquid and gas), and they are still so complex that they require a lot of transformations to become useful products.

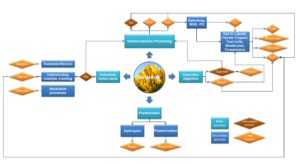

In addition, although there are many different types of oil (mainly depending on their geographical origin), their processing is quite similar. This allows the oil industry to use very well established and standardized processes, which do not vary greatly from one refinery to the other. On the contrary, the variability of biomass is much higher. Forestry waste and municipal solid waste are typical examples of very different types of biomass. They are basically carbon, hydrogen and oxygen, but they differ a lot in density, moisture, inorganic content and morphology. This can be either problematic or beneficial. As there are plenty of different processes to transform biomass in useful products, it is extremely difficult to standardize their engineering design increasing the costs for the equipment in the early stages of their development hindering their deployment. The advantage is that, once those processes are developed, see figure 2).

Figure 2. Potential routes for biomass transformation, process integration and the products obtained.

What is the current stage of development of biorefineries? Well, that depends on the type of process we look at. Technologies like anaerobic digestion or gasification are already available in industry. From 2022, the United Kingdom will have more than 60 MW of installed electric power in plants using through biomass gasification, and Germany is already injecting biogas (an equivalent to natural gas made from biomass through anaerobic digestion) in their gas grid. However, other processes like pyrolysis, fermentation or hydrolysis are still far from the industrial application. This means that some parts of what a biorefinery can be are already commercially available while others still need to be further improved. In addition, one of the main challenges of the development of biorefineries is the integration of the different units into a single facility, trying to optimize the whole process. In this integrated system, the excess of energy released in an operation could be used in another operation, or byproducts from a particular process can be exploited to generate other valuable products somewhere else in the biorefinery.

However, regardless of their development, all biorefining technologies still need to decrease their costs to become competitive against oil-based technologies. It is important to bear in mind that the oil industry comes from more than a century of strong industrial and technological development (and strong subsidies) that allowed them to optimize their processes and minimize their costs. But biorefineries have already travelled part of the way to be a sustainable competitor for the oil industry, and we need them if we really want to minimize the impact of climate change. After several years working on the development of thermochemical processes (pyrolysis, gasification, catalytic upgrading) for biomass transformation I am convinced that we are getting closer to sustainably fulfil our needs and biorefineries are part of the solution.

By Dr. Jose M. Bermudez. Senior Energy Engineer, Department for Business, Energy & Industrial Strategy. Honorary Research Fellow, Chemical Engineering Department, Imperial College London. SRUK London constituency.

More info:

Institution of Biorefinery Engineers, Scientists and Technologists, www.theibest.org

Sadhukhan, J., Ng, K. S., & Hernandez, E. M. (2014). Biorefineries and chemical processes: design, integration and sustainability analysis. John Wiley & Sons.