In Greek times the olive tree was considered a symbol of serenity, fertility and peace, and it was the root for the development of the ancient Greek culture and most of the Mediterranean one. The olive oil, also known as “the liquid gold” by Homer, obtained from this tree was used not only as food source, but also as source of light, medicine and for cleaning and manufacturing perfumes and cosmetic products.

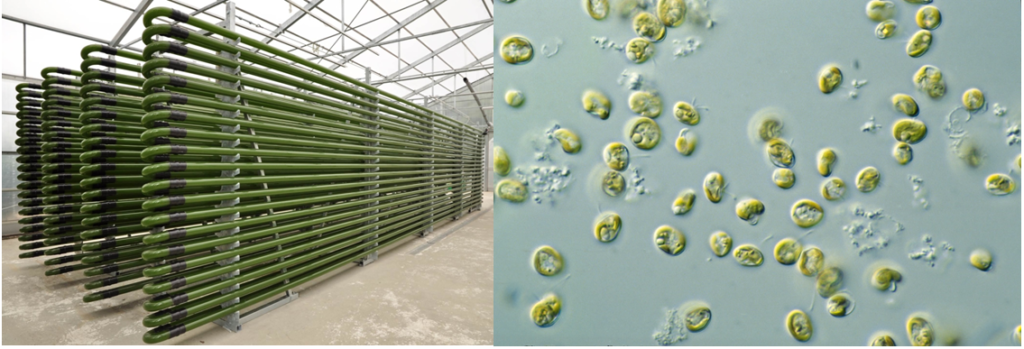

If the “liquid gold” stimulated the development of the Mediterranean culture, currently the products created from microalgae sources, the “green gold”, are the ones that are changing what we and our animals eat, the origin of the dyes used in the manufacturing of our clothes, the drugs that we consume, the creams and cosmetic products that we use and the energy that burn to fuel our vehicles and fly. And, where is this “green gold” coming from? The answer is from the algae. These could be considered as the equivalents to the terrestrial plants of the aquatic environments, because, similarly to terrestrial plants such as for example the trees, they need the sun light and the atmospheric CO2 to generate the organic matter required for growing through a metabolic process called photosynthesis (Figure 1). Depending on their size it can be distinguished two types of algae: macroalgae, which can be seen at normal sight (for example those algae that are left in the sea shore after a storm), and microalgae, which are so small that we need a microscope to be able to see them. Today, I will be talk about these latter.

Figure 1. Left: picture of a tubular glass photobioreactor (source IGV Biotech); right: picture of microalgae species Pavlova sp. (source CSIRO).

Microalgae, apart from their microscopic size, characterize by being mostly unicellular organisms, living in both freshwater and seawater and by playing a very important role in the planet, as they are responsible of 50% of the total oxygen that we breath. You can read more about this topic in the following blog post, where these microorganisms are called “phytoplankton”. Also, microalgae are constituted by a great species diversity linked to a wide variability of metabolic properties that allow them to adapt to the ever changing environment. This metabolic diversity is currently being explored by the biotechnological industry and it is the topic of the research I have carried out for the last three years at the University of Sheffield as part of the BBSRC funded project “Sustainable bioenergy from microalgae: a systems perspective”. In this sense, under specific culture conditions, microalgae can produce food supplements such as β-carotene or Omega-3 fatty acids, anti-oxidants such as Astaxanthin, sources of proteins, or oils susceptible to be exploited in the food industry or as an energy source (Figure 2).

Figure2. Examples of products from microalgae (source http://www.algaeindustrymagazine.com/special-report-spirulina-part-7/)

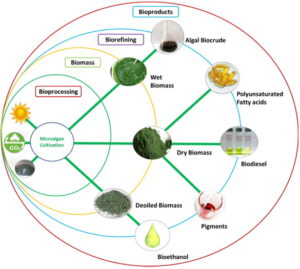

In this last field, microalgae are considered as the source for the biofuels (fuels obtained from organic matter or biomass) of third generation, being better than those fuels obtained from crops (biofuels of first and second generation) because of several reasons: microalgae grow faster than terrestrial plants, produce more biomass and fatty acid yields that are later used in the generation of biofuels, and they require less land use. In addition, microalgae do not compete for the food resources and the freshwater as it happens with the biofuels obtained from crops (i.e. corn crops), and gases enriched with CO2 coming from other industrial activities and wastewaters can be used as the source of carbon and nutrients required for their cultivation. These latter properties make microalgae especially interesting for the sustainable development of the society and the economy (the bioeconomy) because, in theory, for culturing microalgae we would only need the free and endless energy of the sun and a source of CO2 and nutrients that would be recycled from other industrial activities. However, in practice, microalgae cultivation at industrial scales for generating bioenergy is not economically efficient yet. To solve this problem, researchers and industry are currently working together around the world to develop what is called microalgae biorefineries: industrial activities in which the microalgae biomass is used for manufacturing a wide range of products at the same time, including food sources, biofuels, materials, drugs or chemicals (Figure 3), resulting in a reduction of the cost of microalgae cultivation because many benefits are obtained from the same product. In the last years the European Union has funded several research projects focused on the development of microalgae biorefineries and algae farms at pilot scales. If you want to know more about the topic I recommend you to check the following links AlgaeParc, Vimeo, TED talk, it is fascinating how far we have gone in the last years!

Figure 3. Scheme of a microalgae biorefinery (Venkata Mohan et al. 2016 Bioresource Technology 215: 2-12)

Finally, but not less important, microalgae cultivations at industrial scales has another advantage due to is beneficial consequences for the Climate Change. Similarly to terrestrial plants, microalgae also do the photosynthesis, capturing atmospheric CO2 and realising O2 in exchange. In practice, this implies the reduction of CO2 levels in the atmosphere helping to mitigate Climate Change. Also, given their sustainable cultivation, CO2 emissions are minimal and microalgae biofuels are less contaminant than other biofuels. Thus, microalgae energy is cleaner and beneficial for the Climate Change, with a reduced environmental impact.

I hope that with this post I have contributed to open your eyes to the “green gold” revolution that microalgae are for the economic development of our society. I would like to invite to go out there and search in the supermarkets, drugstores, and restaurants for those products that are coming from microalgae. You will be gladly surprised!

By Dr María Huete-Ortega. Postdoctoral researcher, Department of Chemical and Biological Engineering, University of Sheffield, SRUK Yorkshire Constituency.